77779193永利是冶金部、中国有色金属总公司矿山节能推广站的直属企业,是集矿用节能风机的开发、研制、设计、生产和销售一体化的现代化的风机制造企业,山东科技大学产学研基地,山东省矿用风机工程技术研究中心。

公司地处山东省淄博市周村经济开发区境内,北靠济青高速公路,南邻309国道,距淄博火车站仅10多公里,交通十分方便。我公司已有多年的生产实践经验,拥有一批高素质的技术与职工队伍。现有职工136人,其中工程技术人员38人,占地面积26000m2,工艺先进、检测手段齐备,具有一套完善的质量保证体系,已取注册资金5800万元,总资产2600万元,年销售收入9600多万元,在全国风机行业中排名中型一档企业。公司技术力量雄厚、生产得了ISO—9001国际质量体系认证,公司现为省级“重合同、守信用”企业,连年被评为AA级信用企业。

本公司现致力于开发和生产FKCDZ、FKZ、FKD系列金属矿用节能通风机,FBCDZ、FBCZ、FBD系列煤矿用防爆节能主通风机和对旋式局部通风机,煤气加压风机,通用离心与轴流式通风机,纺织轴流式通风机,高温风机和特种风机等产品,共有100多个系列1000余种规格型号。

新闻资讯

•02/23 行业投资力度,加速通用机械经济发展

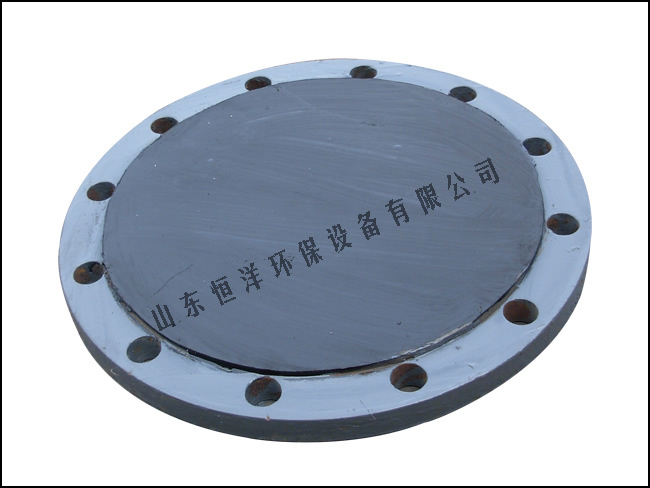

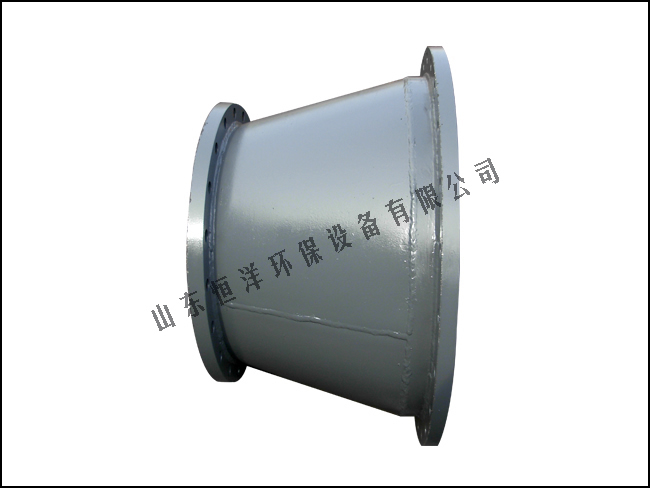

•04/02 客户来厂考察衬胶、衬塑管道

•12/09 精己二酸项目雨中新景

•12/08 国电泰安2x350MW热电联产机组烟气脱硫工程

•07/28 我国核电已形成规模化发展格局